High-End Residential – Full Mechanical Package, Checkley

Project Overview

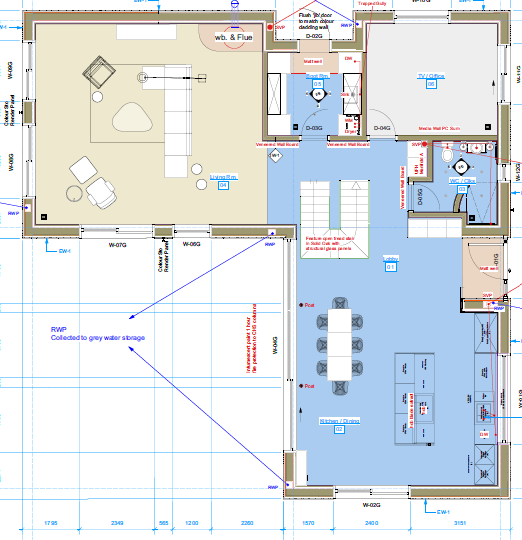

Sparta Mech Ltd were appointed to deliver the complete mechanical services package for a high-end, architect-designed private residence in Checkley, Herefordshire.

The project was designed around low-carbon heating, maximum controllability and long-term performance, with a fully integrated solution covering heating, domestic hot water, plumbing, ventilation and private water treatment.

The plant was designed with a dedicated garage plant room to keep primary equipment isolated from the main living accommodation while maintaining full accessibility, reliability and clean presentation.

Scope of Works

End-to-end delivery of the complete mechanical package.

Air Source Heat Pump

Stiebel Eltron WPL25 ASHP with weather compensation, delivering efficient low-temperature heating with 400L DHW cylinder.

Underfloor Heating

Roth UFH system installed throughout both floors with zoned controls for accurate room temperature management.

MVHR Ventilation

Vent-Axia whole-house MVHR system providing balanced supply and extract ventilation with heat recovery.

Borehole Water Treatment

Complete water treatment system with constant pressure pump, filtration, UV sterilisation and treated water distribution.

High-End Plumbing

Full domestic plumbing package including luxury bathrooms, en-suites and cloakrooms with high-end sanitaryware.

Plant Room Design

Dedicated insulated plant room in garage with clean presentation, insulated pipework and full accessibility for servicing.

Delivery at Scale

Demonstrating consistent mechanical installations across multiple plots.

Quality & Workmanship

Quality control is a core element of our delivery model.

Weather compensation enabled to automatically adjust flow temperature based on outdoor conditions

Fully insulated distribution pipework including insulated underground services to reduce heat loss

Zoned UFH controls designed to maximise heat pump efficiency and provide stable comfort

MVHR system commissioned and air balanced to achieve design airflow performance

UV sterilisation and particle filtration ensuring potable water quality from private borehole

Clean plant room presentation with reliable arrangement for long-term serviceability

Sustainability & Energy Performance

- Low-carbon heating via air source heat pump technology

- Weather compensation reduces flow temperature during milder conditions

- MVHR heat recovery supports energy efficiency

- Low temperature distribution designed to suit heat pump operation

- Zoning and control strategy minimises unnecessary runtime

Programme & Reliability

Structured delivery to support continuous progress with minimal disruption.

Project Commencement

Works commence with first fix installations and plant room setup.

System Integration

Installation of ASHP, UFH, MVHR, water treatment and plumbing systems with coordinated delivery.

Project Completion

Final commissioning, system handover and client training on all integrated systems.

Project Outcome

This project demonstrates our capability to deliver at scale.

Renewable Heating

ASHP with weather compensation delivering efficient low-carbon heating

Integrated Systems

Five fully integrated mechanical systems working together seamlessly

Water Quality

Private borehole treatment ensuring safe potable water throughout

High-End Finish

Luxury bathroom installations with attention to detail and quality

Full Handover

Complete commissioning, setup and operating guidance provided

Ready to Discuss Your Project?

Contact us for reliable mechanical services delivery on your residential or commercial development.